-

Step 1:

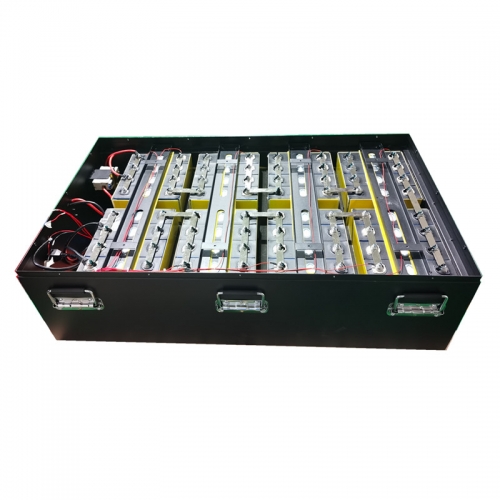

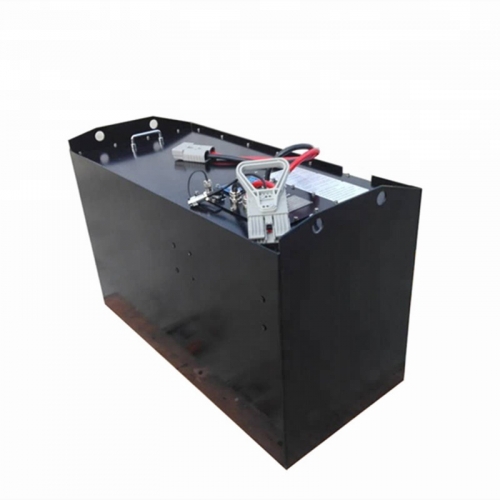

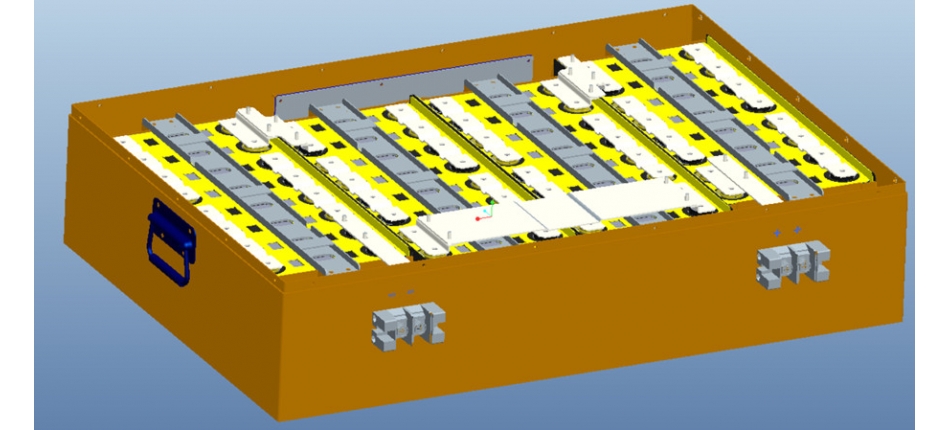

Clear the technology requirement of EV battery pack with customer, know the usage environment and the required functions. According to these information, Design the internal and external structure drawing of battery pack, make sure battery cells and parts are well fixed in the case and fully insulated. Reduce the risk of short-circuit and virtual welding in moving and vibration.

-

Step 2:

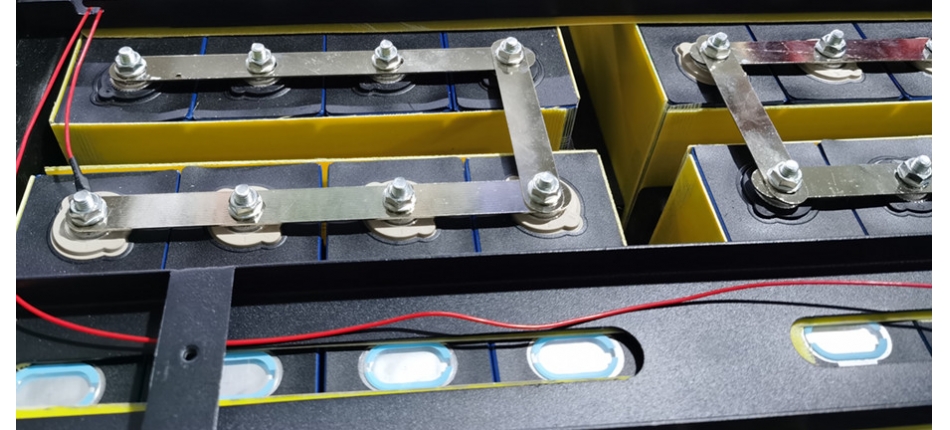

Arrange the purchase of battery pack case according to the drawing -- Custom connection Busbar according to cell’s distance -- rewrite communication protocols of BMS according to function requirements, each step need professional and experienced engineers’ careful work.

-

Step 3:

When everything are ready, finish assembly work and test battery pack performance with test equipment. Test BMS communication function whether normal work, test battery pack charge/discharge voltage and total capacity whether meet requirements. And pass other test required.

Related products